Introduction to quality sampling

AQL and sampled inspection plans

In manufacturing, AQL stands for Acceptable Quality Level. AQL represents the poorest level of quality for an item that you consider acceptable. Quality professionals use AQL sampling tables to determine the accept and reject criteria of inspection material. Inspection material can be raw goods, purchased parts, in-process production, final products or services, pre- and post-shipment parts, and so on.

Sampled inspection ensures maximum quality by sampling/inspecting the fewest items while minimizing risk, time, and cost. Most companies either over sample or under sample because the overhead involved in adaptively adjusting sampling rates based on past performance is difficult to do manually.

Sampled inspection uses predefined rules to determine a quantity of items that must be inspected prior to being added to stock. In FactoryLogix, you can create multiple sampling plans for different types of items based on your quality criteria.

FactoryLogix supports quality sampling in the following areas in manufacturing operations:

Incoming materials inspection

In-process quality sampling

Sampled inspection plans ensure maximum quality by sampling/inspecting the fewest items while ensuring maximum quality and minimizing risk, time, and cost. Quality inspectors depend on these plans to determine the number of items to inspect.

Stages of a typical quality sampling plan

Select an appropriate statistical quality sampling plan

Determine the AQL percentage

Specify the sampling plan parameters and rules

Establish the sample size and the accept/reject criteria

Randomly select items for sampling or select items for sampling at regular intervals

Inspect each item for the specified inspection criteria

Accept or reject the remaining items in the lot

How to select a quality sampling plan

Selecting an appropriate quality sampling plan depends on your inspection needs, for example:

Monitoring a production line

Inspecting items for specific defects, tolerances, measurements, etc.

Inspecting items for safety issues

Inspecting incoming items/parts for inspection

Before you select a quality sampling plan, you need to determine the inspection criteria. Can you allow any defects during a sampled inspection? Do you have a record of past defects for the items being manufactured?

There are many statistical AQL sampling plans. Some plans are used for lot inspection and some are used for production inspection. Certain plans focus on issues related to safety; others are used to inspect both major and minor product features. When defect levels decrease, some plans allow for reduced sampled inspection percentages. Some plans allow for defects or mistakes in inspection and others don't.

Determine the AQL percentage

The AQL percentage depends on the feature of the item being inspected. If the feature has high importance, you select a lower AQL. The AQL percentage can be as low as .01 percent or as high as 10 percent. You typically select a number in between .01 percent and 10 percent.

In-process quality sampling

Process engineering or quality engineering configures a sampling plan type to achieve the desired AQL (Acceptable Quality Limit).

FactoryLogix supports these sampling plan types:

MIL-STD-105E (ANSI/ASQ Z1.4)

MIL-STD-1916 – Accept on Zero (c=0)

Squeglia Zero-Based Plan

Simple Sample Plan

You can apply switching rules to adaptively increase or decrease the sampling frequency automatically over time, based on historical process outcomes.

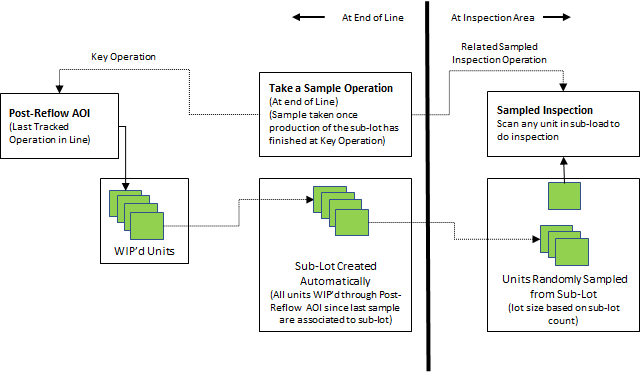

FactoryLogix in-process quality sampling allows you to perform sampled inspections more frequently by dynamically breaking down a production lot into smaller sub-lots, then performing a sampled inspection on the sub-lots.

Conceptual factory floor and process flow

Dynamically builds sub-lots of production items to be sampled.

Automatically calculates the sample size for inspection based on the lot size using the AQL strategy and level you established during configuration.

Operators are notified by FactoryLogix to take a sample at a specific time interval or (depending on configuration) take samples at any time.

The result of the sample, in combination with the sampling plan, determines automatic disposition of the lot.

None of the units in the lot will be allowed to be processed downstream until the sampling inspection is passed.

If the lot fails the sample inspection, the items in the lot are quarantined by (a) being rerouted to a quarantine station or (b) disallowed from proceeding downstream.

If routed to a quarantine station, FactoryLogix can induce a Material Review Board (MRB) workflow and manage that process (if you own that FactoryLogix option).

Flexible process flow configuration

When you configure the process flow for in-process sampled inspections, consider these three key target locations:

The process location where the sample is parsed out from the total lot (Take a Sample Operation)

The process location where the sampled units are actually inspected (Sampled Inspection)

The operation that determines the items in the lot—typically the outbound WIP transaction of the workstation before taking a sample (Key Operation)

Note

The three key target locations can be the same physical process location or any combination of coincident or separate locations.