Search and filter options for data sources

Depending on the selected data source, you can search and filter by multiple fields/criteria in the FactoryLogix database.

Log into the Analytics client application.

Select Data Miner/Data Analysis to start DataMiner.

Create a workbook or open an existing workbook.

On the left side of the window under Data Sources, select a category to display the data sources for the category.

Double-click a data source to view its associated tabs and options.

Important

The available search and filter options depend on the data source you select. For example, on the Products tab, you only see the GRN option for the GRN Status and Material Purchase Orders data sources. If an option isn't available for the selected data source, it will be dimmed.

Propagate Value button

The Propagate Value button (the Blue arrow) ![]() propagates the value of a search field from one data source to another data source—or to all data sources—within a single workbook (if they have the same data sources available to the data set).

propagates the value of a search field from one data source to another data source—or to all data sources—within a single workbook (if they have the same data sources available to the data set).

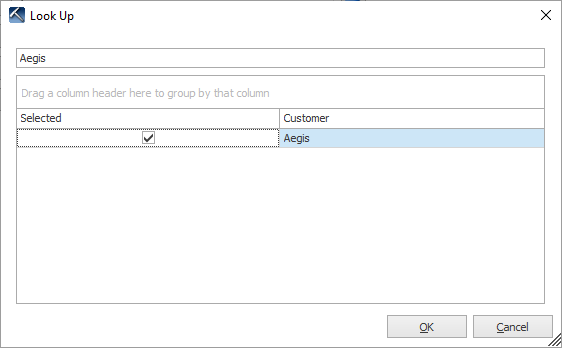

Look Up dialog

When you select some search/filter options (Customers, for example), a Look Up dialog displays. When you start typing, the dialog displays data matching the criteria you type.

Tip

Enter an asterisk * character to return all data quickly in a Look Up dialog.

Here is an example of the search and filter tabs for the NPI/CAD-BOM data source. (The individual tabs and options change depending on the data source category and individual data source you select.)

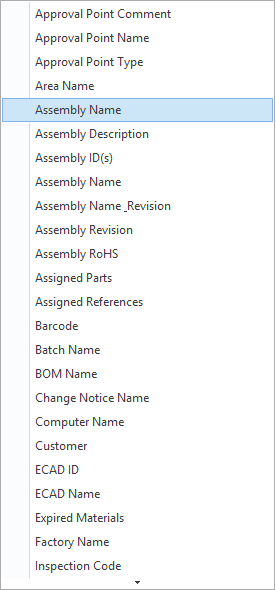

Search and filter options (by tab name)

The following table (organized alphabetically, by tab name) describes the DataMiner search and filtering tabs and the options available on each tab.

Note

Not all tabs and filtering options are available for all data sources; the options displayed are specific to the data source you select.

Tab | Search and filtering options |

|---|---|

Barcode Template (System Administration category) |

More information: Create a barcode template |

Batch Type (Miscellaneous category) |

|

BOM Options |

More information: Part Library, Configurable assemblies |

Change Notice Type |

More information: Approvals and sign-off |

Data Source Join Properties |

|

Group By |

|

Job Status |

More information: Entry/exit conditions and actions for product tracking |

Location |

More information: Process flow operations |

Logistics |

More information: Printed label templates for materials and transport orders, Using Logistics |

Materials |

More information: View archived records in the Trace window |

Non-Conformances |

More information: What is a non-conformance? |

OEE Quality Metrics |

More information: Configure OEE |

Operator Feedback Status (Production and WIP Tracking category) |

|

Options |

|

Options (Inventory, Material and Traceability category) |

|

Options (Archive and Restore History, Miscellaneous category) |

More information: Archiving, Restore archived data |

Options (DPMO (IPC-7912)), Quality and test category |

More information: DPMO and opportunity count methodologies |

Options (Production Scheduling, Production and WIP Tracking category) |

More information: Production planning and scheduling |

Options (Productivity Over Time, Production and WIP Tracking category) |

|

Options (Quality, Quality and Test category) |

More information: Defect collection in the Hot Spot Viewer |

Options (SPC Measurements, SPC Category) |

More information: Use dashboard gadgets |

Options (WIP, Production and WIP Tracking category) |

Here are some definitions to help you understand how WIP calculations are done in DataMiner:

More information: Entry/exit conditions and actions for product tracking |

Orders (Material Purchase Orders, Logistics category) |

More information: Material Purchase Orders (POs) |

Part Relationship |

More information: Link part numbers to create relationships |

Products |

More information: Libraries |

Receiving Options |

More information: Vendors and logistics |

Resources |

More information: Create a factory and set up factory resources |

Search by UID Options |

More information: Using Logistics, UID Format |

Sites | The factories/sites you query for enterprise data. More information: Using the Enterprise Warehouse |

SQL (User Defined) |

Note When entering SQL statements, you can get help by right-clicking anywhere in the SQL area to display a menu of SQL commands.  |

Sub Group |

|

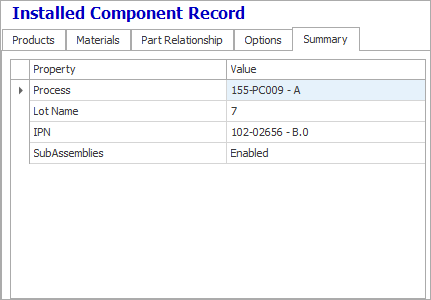

Summary | The Summary tab shows a summary of all search and filtering selections from the other tabs for the selected data source.  |

Time | Date Time Range:

Note Under Date Time Range, the first drop-down is sometimes dimmed, but it does provide a reference to help you understand what the Time drop-down indicates. For example, when you select the Time tab for the Tool Usage History data source (Material and Traceability category), the drop-down indicates Calibration Expiration Date as a reference to help you select the appropriate time from the second drop-down. Time drop-down:

|

User Details (User Detail, System Administration category) |

More information: Create and manage users and groups, About user roles |

Note

To access advanced filtering options and data manipulation techniques for your FactoryLogix data, see Group, sort, filter, and format workbook data