Select default administrator role permissions

ADMINISTRATOR

All permissions are enabled for all categories for the default administrator role.

Important

Although you can modify the default administrator role, we recommend creating your own roles and not modifying the default administrator role.

The default administrator role can manage permissions in the following categories and sub-categories of the FactoryLogix system. Each category contains individual permissions that can be enabled or disabled for any additional administrator roles that are created.

Note

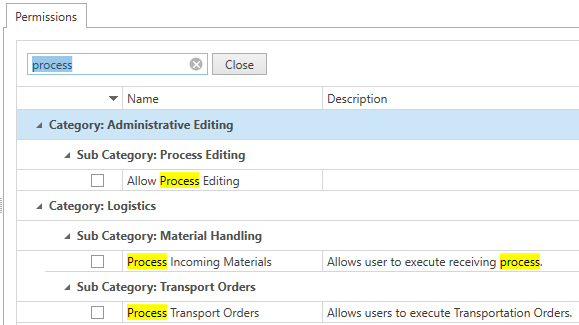

To quickly search for a permission, select the first column header on the Permissions tab, press Ctrl+F, enter the search term, then press Enter. The search results are highlighted in Yellow as shown in the following illustration.

Tip

Use the following table to help you track the permissions assigned to the administrator role(s) in your organization.

Employee: _______________________________________________________________________

Role: _____________________________________________________________________________

Notes: ___________________________________________________________________________

Category | Sub-category | Permissions | Enabled? |

|---|---|---|---|

Administrative Editing | Checkout Management | Manage Checkout: Manage checkouts for BOMs, CAD files, and processes in the NPI Process Definition window. More information: Check out a BOM, CAD, or process for editing Remove Checkout: Remove another user's checkout of a BOM, CAD file, or process in the NPI Process Definition window. More information: Remove checked out processes | |

Administrative Editing | Process Editing | Allow Process Editing: Edit a process flow in the NPI Process Definition window (operations, steps, activities, and Active Work Instructions). More information: Check out a BOM, CAD, or process for editing, Create an Active Work Instruction | |

Administrative Editing | Product Editing | Allow Product (Assembly) Editing: Edit assemblies and assembly revisions in the NPI client application. More information: Assembly Library, Create, modify, search, duplicate, or delete an assembly | |

Archiving | Archive Data | Archive: Schedule records for archiving, archive records, add records to the Archive queue, restore and review records scheduled for processing/archiving (NPI > System Configuration > Archiving). Record types: batches, GRNs, assemblies, processes, receiving processes, and (rearchive) machine performance data. Delete Archive Queue Items: Delete records from the Archive queue (NPI > System Configuration > Archiving). Record types: batches, GRNs, assemblies, processes, receiving processes, and (rearchive) machine performance data. More information: Archiving | |

Archiving | Archive Queue | View Archive Queue: View records to be archived or restored. Record types include: batches, GRNs, assemblies, processes, receiving processes, and (rearchive) machine performance data. More information: Active Archive Queue window | |

Archiving | Restore Archived Data | Delete: Delete items to be queued for archiving or restored. Restore Archived Items: Restore archived items or add items to the Restore Archive queue. Record types include: batches, GRNs, assemblies, processes, receiving processes, and (rearchive) machine performance data. More information: Restore archived data | |

Archiving | Settings | Allow editing of Archive Settings: Edit archive settings and scheduling in the NPI client application. Allow Viewing of Archive Settings: View archive settings and scheduling in the NPI client application. More information: Archive settings and scheduling options | |

Enterprise Reporting | Settings | Use the Enterprise Reporting Tool: Connect and use the Enterprise Warehouse reporting tool and website for enterprise-level data transaction processing. The Reporting tool allows you to combine and synthesize data from ERP and PLM systems, DataMiner, and other BI systems to produce multi-site, enterprise-level data reports and analytics. | |

FactoryLogix Website | Remember Me | Allow: Use the Remember Me checkbox to remain logged into the FactoryLogix website. (When disabled, users will be warned that their session will not be remembered.) More information: Using the FactoryLogix Website | |

Logistics | Edit Material Functions | Empty UID: Zero out or change the quantity of a UID. Reset UID Quantity: Adjust/set a UID quantity. Reverse Depletion: Allows users to reverse depletion of a UID. Splice UID: Splice material UIDs. Split UID: Split material UIDs. | |

Logistics | GRN | Create: Create new Goods Receipt Notes (GRNs) in the Logistics client application. Delete: Delete existing GRNs in the Logistics client application. Edit: Modify existing GRNs in the Logistics client application. Edit reason texts for material scrapping: Add new reason texts for material scrapping. More information: Create a Goods Receipt Note (GRN), Material Purchase Orders (POs), About logistics in FactoryLogix | |

Logistics | Material Handling | Accept Materials: Accept materials into stock. Allow the User to Remove Reserved Material from Stock: Remove reserved materials from stock. Change Part Number: Change the part numbers of existing materials and re-label them. Close MSD Materials: Close MSD UIDs. Close Solder Paste Materials: Close solder paste UIDs. Move To Stock Location: Move materials to any stock location. Open MSD Materials: Open MSD UIDs. Open Solder Paste Materials: Open solder paste UIDs. Process Incoming Materials: Execute receiving processes. Remove From Stock Location: Remove items from any stock location. Re-Print Label: Reprint UID labels. Reset MSD Materials: Reset the exposure time for MSD parts. Reset Solder Paste: Reset the exposure time for solder paste. More information: About logistics in FactoryLogix, Manage IPN logistics | |

Logistics | Material Reservations | Allow Alternates when part reordering is restricted: The Alternate Part tab is available in the Material Requisition gadget, but only allowed part numbers and their Alternate part numbers will be visible. Allow reordering of any part: The Part Library tab and the Show Entire BOM button are available in the Material Requisition gadget. Allow reordering of any part from BOM: The Part Library tab is not available and the Show Entire BOM button is available in the Material Requisition gadget. Allow to reserve material during reorder: Reserve materials when making material requisitions. More information: Manage IPN logistics | |

Logistics | Part Relationships | Allow Part Relationship Creation: Create MPN or VPN relationships in the NPI client application if they don't exist when creating new material inventory. More information: Link part numbers to create relationships, Part Library | |

Logistics | Receiving Option Codes | Create Receiving Option Codes: Create new option codes for receiving. Delete Receiving Option Codes: Delete existing option codes for receiving. Edit Receiving Options Codes: Modify existing option codes for receiving. Read Receiving Option Codes: Read existing option codes for receiving. More information: Option codes for configurable assemblies | |

Logistics | Remove Shipment | Allow Remove Shipment: Access and remove selected shipments. | |

Logistics | Shipping Settings | Allow Editing of Shipping Settings: Change the settings used for shipping. | |

Logistics | Suggested Stock Locations | Allow Clearing of Stock Location Full Flag: Edit the Is Full flag on a stock location. Allow Overriding of Material Group Stock Selection: Override the requirement that a stock must have a matching material group. Users with this permission can stock the material even if the material group isn't on the stock resource. Allow Overriding of Suggested Stock Locations: Override the suggested stock location and select a different stock location. | |

Logistics | Transport Orders | Allow Overriding of Transport Order Priority: Override the current priority set for transport orders. Cancel Transport Orders: Cancel selected transport orders. Create Transport Orders: Create a new transport order manually. Process Transport Orders: Execute selected transport orders. Shorted Transport Order Item: Short the UID or part being called out by a transport order item and create a new missing order containing the shorted UID. Swap Transport Order Item: Change the UID or part being called out by a transport order item. View Transport Orders: View transportation orders. More Information: Production planning and scheduling, Reorder parts | |

Logistics | WBS Bridge | Allow WBS Bridge Editing: Create or delete a Work Breakdown Structure (WBS) bridge in the WBS Bridge Library. View WBS Bridge: View WBS Bridge data. | |

New Product Introduction | Approval Processes | Create Approval Processes: Create new approval processes to send automated emails to members of sign-off groups to request approval of one or more areas of an overall process (NPI > Templates and Standards > Define Approval Processes). Delete Approval Processes: Delete existing approval processes (NPI > Templates and Standards > Define Approval Processes). Edit Approval Processes: Modify existing approval processes (NPI > Templates and Standards > Define Approval Processes). Read Approval Processes: Read existing approval processes (NPI > Templates and Standards > Define Approval Processes). More information: Approvals and sign-off | |

New Product Introduction | Barcode Templates | Create Barcode Templates: Create new barcode templates (NPI > Templates and Standards > Barcode Templates). Delete Barcode Templates: Delete existing barcode templates (NPI > Templates and Standards > Barcode Templates). Edit Barcode Templates: Modify existing barcode templates (NPI > Templates and Standards > Barcode Templates). Read Barcode Templates: Read existing barcode templates (NPI > Templates and Standards > Barcode Templates). More information: Barcode templates, Create a barcode template | |

New Product Introduction | Certifications | Apply or Remove Certifications: Apply or remove certifications. Create Certifications: Create new certifications. Delete Certifications: Delete existing certifications. Edit Certifications: Make changes to existing certifications. More information: Create a user | |

New Product Introduction | Change Notices | Create Change Notices: Create new change notices (NPI > Templates and Standards > Define Approval Processes area). Delete Change Notices: Delete existing change notices (NPI > Templates and Standards > Define Approval Processes). Edit Change Notices: Modify existing change notices (NPI > Templates and Standards > Define Approval Processes). Read Change Notices: Read existing change notices (NPI > Templates and Standards > Define Approval Processes). More information: Approvals and sign-off | |

New Product Introduction | Certifications | Apply or Remove Certifications: Apply or remove certifications in the Operation Properties dialog (certifications library). Create Certifications: Create new certifications in the Operation Properties dialog (certifications library). Delete Certifications: Remove certifications in the Operation Properties dialog (certifications library). Edit Certifications: Modify certifications in the Operation Properties dialog (certifications library). More information: Add a new operation to a process flow, Create a user | |

New Product Introduction | Change Notices | Create Change Notice: Create a new change notice, select the affected items from a list, and add any necessary details and/or attachments. You can also duplicate (copy) an existing change notice. Delete Change Notice: Search for and delete an existing change notice. Edit Change Notice: Search for and edit an existing change notice. Read Change Notice: Search for and view any existing change notice. More information: Manage change notices | |

New Product Introduction | Conditions & Actions Library | Create Conditions & Actions: Create new conditions and actions for an operation (NPI > Libraries > Conditions and Actions Library). Delete Conditions & Actions: Delete existing conditions and actions for an operation (NPI > Libraries > Conditions and Actions Library). Edit Conditions & Actions: Modify existing conditions and actions for an operation (NPI > Libraries > Conditions and Actions Library). Read Conditions & Actions: Read existing conditions and actions for an operation (NPI > Libraries > Conditions and Actions Library). More information: Conditions and Actions Library, Specify entry/exit conditions and actions for an operation, Entry/exit conditions and actions for product tracking | |

New Product Introduction | Customer Library | Create Customer Library: Create a new Customer Library (NPI > Libraries > Customer Library). Delete Customer Library: Delete an existing Customer Library (NPI > Libraries > Customer Library). Edit Customer Library: Modify an existing Customer Library (NPI > Libraries > Customer Library). Read Customer Library: Read an existing Customer Library (NPI > Libraries > Customer Library). More information: Customer Library | |

New Product Introduction | Define Sampling Plans | Create Sampling Plan: Create a sampling plan for sampled inspections and/or specify a default sampling plan. Delete Sampling Plan: Select and delete an existing sampling plan. Edit Sampling Plan: Modify the parameters for an existing sampling plan, disable an existing sampling plan, and/or specify a default sampling plan. Read Sampling Plan: Read Only access to select and view an existing sampling plan. More information: Introduction to quality sampling, Add a new quality sampling plan | |

New Product Introduction | Document Library | Create Document Library: Create a new document library and specify its properties. Edit Document Library: Modify an existing Document Library including: upload and link documents, create new folders and edit folder properties, find/replace linked document file paths, and search for documents. Delete Document Library: Select and delete an existing Document Library. Read Document Library: Read Only access to select and view an existing Document Library. More information: Document Library | |

New Product Introduction | E-mail Templates | Edit E-mail Template: Create, edit, and delete email templates. View E-mail Template: Read Only access to email templates. More information: Create an email template | |

New Product Introduction | Factory Resources | Create Factory Resources: Create new factory resources (NPI > Templates and Standards > Factory Resources). Factory resources include factories, areas, lines, workstations, clustered workstations, tempering ovens, cold storage, and stock locations. Delete Factory Resources: Delete existing factory resources (NPI > Templates and Standards > Factory Resources). Factory resources include factories, areas, lines, workstations, clustered workstations, tempering ovens, cold storage, and stock locations. Edit Factory Resources: Modify existing factory resources (NPI > Templates and Standards > Factory Resources). Factory resources include factories, areas, lines, workstations, clustered workstations, tempering ovens, cold storage, and stock locations. Read Factory Resources: Read existing factory resources (NPI > Templates and Standards > Factory Resources). Factory resources include factories, areas, lines, workstations, clustered workstations, tempering ovens, cold storage, and stock locations. More information: Create a factory and set up factory resources | |

New Product Introduction | Global Operations | Create Global Operation: Create a new global operation alias and associated Operator Interface template, a new global packout operation, or a new global shipping operation. Delete Global Operation: Delete an existing global operation alias, global packout operation, or global shipping operation. Edit Global Operation: Edit an existing global operation alias, global packout operation, or global shipping operation. Read Global Operation: Read Only access to view an existing global operation alias, global packout operation, or global shipping operation. More information: Global operations | |

New Product Introduction | Global Text Library | Create Global Text: Create new global text elements (NPI > Templates and Standards > Work Instruction Templates) for active work instruction templates, email templates, and visual aids. Delete Global Text: Delete existing global text elements (NPI > Templates and Standards > Work Instruction Templates) for active work instruction templates, email templates, and visual aids. Edit Global Text: Edit existing global text elements (NPI > Templates and Standards > Work Instruction Templates) for active work instruction templates, email templates, and visual aids. More information: Create an Active Work Instruction template, Add items to a template | |

New Product Introduction | Inspection Code Associations | Edit Inspection Code Associations: Edit existing inspection code associations. Read Inspection Code Associations: Read Only access to view existing inspection code associations. More information: Create and manage inspection codes | |

New Product Introduction | Inventory Management | Allow New Inventory Bypassing Receiving Process: Allows the user to add new inventory and bypass the normal receiving process associated with the part/vendor. Block Inventory: Prevent inventory from being processed or used immediately or transacted in Production. Create Inventory: Create a new inventory (NPI > Logistics > Inventory). Delete Inventory: Delete an existing inventory (NPI > Logistics > Inventory). Edit Inventory: Modify an existing inventory (NPI > Logistics > Inventory). Read Inventory: Read an existing inventory (NPI > Logistics > Inventory). Unblock Inventory: Allows a user to remove usage restrictions from blocked inventory. More information: Quarantine/block processing of production units and materials | |

New Product Introduction | Just-In-Time Flows | Create JIT Flow: Create a Just-In-Time (JIT) reroute/flow for a process definition in Production. Edit JIT Flow: Modify a Just-In-Time (JIT) reroute/flow in a process definition in Production. Read JIT Flow: Read-Only permission to view a Just-In-Time (JIT) reroute/flow in Production. More information: Out of route operations and reroutes | |

New Product Introduction | Kit Group Setup | Edit Kit Groups: Allows a user to create, edit, and delete kit groups. View Kit Groups: Grants Read Only access to view kit groups. More information: Kit groups, Set up a kit group | |

New Product Introduction | Manufacturer Library | Create Manufacturer Library: Create a new Manufacturer Library (NPI > Part Library > Manufacturer Part Numbers). Delete Manufacturer Library: Delete an existing Manufacturer Library (NPI > Part Library > Manufacturer Part Numbers). Edit Manufacturer Library: Modify an existing Manufacturer Library (NPI > Part Library > Manufacturer Part Numbers). Read Manufacturer Library: Read an existing Manufacturer Library (NPI > Part Library > Manufacturer Part Numbers). More information: Manage the manufacturer library | |

New Product Introduction | Material Purchase Orders | Edit Material Purchase Orders: Allows a user to create, edit, and delete material purchase orders. View Material Purchase Orders: Grants Read Only access to view material purchase orders. More information: Material Purchase Orders (POs) | |

New Product Introduction | Operation Groups | Create Operation Groups: Create new operation groups in the NPI Process Definition window. (NPI > Process Engineering). Delete Operation Groups: Delete existing operation groups in the NPI Process Definition window (NPI > Process Engineering). (Requires permission for Delete Operations to delete an operation group that contains multiple operations.) Edit Operation Groups: Modify existing operation groups in the NPI Process Definition window (NPI > Process Engineering). Read Operation Groups: Read Only access to view the properties of an existing operation group in the NPI Process Definition window (NPI > Process Engineering). More information: Process flow operations | |

New Product Introduction | Operation Interface Templates | Create Operator Interface Template: Create a new Operator Interface template. Delete Operator Interface Template: Delete an existing Operator Interface template. Edit Operator Interface Template: Modify an existing Operator Interface template. Read Operator Interface Template: Read an existing Operator Interface template. More information: Operator Interface templates, Create an Operator Interface template | |

New Product Introduction | Operations | Create Operations: Create new operations in the NPI Process Definition window. (NPI > Process Engineering). Delete Operations: Delete existing operations in the NPI Process Definition window (NPI > Process Engineering). Edit Operations: Modify existing operations in the NPI Process Definition window (NPI > Process Engineering). Read Operations: Read Only access to view existing operations in the NPI Process Definition window (NPI > Process Engineering). More information: Add a new operation to a process flow | |

New Product Introduction | Operator Feedback | Edit Operator Feedback: Edit operator feedback. More information: Gadgets for Operator Interface templates | |

New Product Introduction | Part Library | Add or delete Documents on Assemblies with a Released Process: Delete documents on assemblies that have one or more process revisions which have been released to Production. Allow Revision Re-Ordering: Revise part reordering. Create Part Library: Create a new Part Library (NPI > Libraries > Part Library). Delete Part Library: Delete an existing Part Library (NPI > Libraries > Part Library). Edit Part Library: Modify an existing Part Library (NPI > Libraries > Part Library). Read Part Library: Read an existing Part Library (NPI > Libraries > Part Library). Sampling Plan AQL/Verification Override: Override verification of sampling plans and AQL. More information: Part Library | |

New Product Introduction | Printed Label Templates | Edit Printed Label Templates: Allows a user to create, edit, and delete printed label templates. View Printed Label Templates: Allows Read Only access to view printed label templates. More information: Create or duplicate printed label templates | |

New Product Introduction | Priorities | Create Priorities: Create new priorities. Delete Priorities: Delete existing priorities. Edit Priorities: Modify existing priorities. Read Priorities: Read existing priorities. | |

New Product Introduction | Process Templates | Create Process Templates: Create new process templates. Delete Process Templates: Delete existing process templates. Edit Process Templates: Modify existing process templates. Read Process Templates: Read existing process templates. More information: Create a process, step, or operation template | |

New Product Introduction | Processes | Allow Post-Release BOM Editing of Alternate Parts: Users can add or remove alternate parts to BOM line items of a process that is already released to production. Create Processes: Create new processes. Delete Processes: Delete existing processes. Edit Processes: Modify existing processes. Read Processes: Read existing processes. More information: Process flows | |

New Product Introduction | Production Scheduling | Create Schedule: Create a new production schedule. Delete Schedule: Delete an existing production schedule. Edit Schedule: Modify an existing production schedule. Read Schedule: Read an existing production schedule. More information: Production planning and scheduling | |

New Product Introduction | Products | Create Product: Create a new product or assembly. Delete Product: Delete an existing product or assembly. Edit Product: Modify an existing product or assembly. Read Product: Read an existing product or assembly. More information: Create, modify, search, duplicate, or delete an assembly | |

New Product Introduction | Quality Standards | Create Quality Standards: Create/define new quality standards. Delete Quality Standards: Delete existing quality standards. Edit Quality Standards: Modify existing quality standards. Read Quality Standards: Read Only permission to view existing quality standards. More information: Define quality standards | |

New Product Introduction | Recipe Management | Edit Recipe Types: Allows a user to create, edit, and delete recipe types. Edit Recipes: Allows a user to create, edit, and delete recipes. Edit Selection Profiles: Allows a user to create, edit, and delete selection profiles. Edit Selection Types: Allows a user to create, edit, and delete selection types. View Recipe Types: Allows a user Read Only access to view recipe types. View Recipes: Allows a user Read Only access to view recipes. View Selection Profiles: Allows a user Read Only access to view selection profiles. View Selection Types: Allows a user Read Only access to view selection types. More information: Recipe management | |

New Product Introduction | Site Location Management | Edit Site Locations: Provides the ability to define or edit the site/location where a defect was found or indicted (Edit Defect dialog). | |

New Product Introduction | Source Management | Edit Source: Provides the ability to edit the source of a defect indictment (Edit Defect dialog). | |

New Product Introduction | Task Flow Templates | Create Task Flow Templates: Create new task flow templates. Delete Task Flow Templates: Delete existing task flow templates. Edit Task Flow Templates: Modify existing task flow templates. Read Task Flow Templates: Read existing task flow templates. More information: Create a task flow template | |

New Product Introduction | Tasks | Create Tasks: Create new tasks in a project. Delete Tasks: Delete existing tasks in a project. Edit Tasks: Modify existing tasks in a project. Read Tasks: Read existing tasks in a project. More information: Schedule Projects | |

New Product Introduction | Units of Measure | Edit Units of Measure: Create, edit, and delete units of measure in the Templates and Standards area of the NPI client application. View Units of Measure: Allows Read Only access to view units of measure. More information: Specify units of measure | |

New Product Introduction | Vendor Labels | Edit Vendor Labels: Create, edit, and delete vendor labels. View Vendor Labels: Allows Read Only access to view vendor labels. More information: Create a vendor label | |

New Product Introduction | Vendor Library | Create Vendor Library: Create a new Vendor Library (NPI > Libraries > Vendor Library). Delete Vendor Library: Delete an existing Vendor Library (NPI > Libraries > Vendor Library). Edit Vendor Library: Modify an existing Vendor Library (NPI > Libraries > Vendor Library). Read Vendor Library: Read an existing Vendor Library (NPI > Libraries > Vendor Library). More information: Vendor Library | |

New Product Introduction | Work Instruction Templates | Create Work Instruction Templates: Create new Work Instruction templates. Delete Work Instruction Templates: Delete existing Work Instruction templates. Edit Work Instruction Templates: Modify existing Work Instruction templates. Read Work Instruction Templates: Read existing Work Instruction templates. More information: Create an Active Work Instruction template | |

Non-Conformance | Manage Dispositions | Create Dispositions: Create new disposition decisions. Delete Dispositions: Delete existing disposition decisions. Edit Dispositions: Modify existing disposition decisions. Read Dispositions: Read existing disposition decisions. More information: Create disposition decisions | |

Non-Conformance | Non-Conformance | Change Assigned Profile: Allows the user to change the profile of a non-conformance any time before the non-conformance is closed. Create Non-Conformances: Create a new non-conformance. Delete Non-Conformances: Delete an existing non-conformance. Edit Non-Conformances: Modify an existing non-conformance. Non-Conformance Administrator: The Non-Conformance Administrator has the ability to modify any non-conformance, even if a user is not in the user list. Read Non-Conformances: Read Only permission to view an existing non-conformance. More information: Non-conformance review and disposition | |

Non-Conformance | Non-Conformance Profile | Create Non-Conformance Profile: Create a new non-conformance profile. Delete Non-Conformance Profile: Delete an existing non-conformance profile. Edit Non-Conformance Profile: Modify an existing non-conformance profile. Non-Conformance Administrator: The Non-Conformance Administrator has the ability to modify any non-conformance, regardless of whether the user is in the required user list. Read Non-Conformance Profile: Read Only permission to view an existing non-conformance profile. More information: Create a non-conformance About non-conformance profiles | |

Shop Floor | Batch | Allow Batch Prioritization: Prioritize an existing batch. Create Batch: Create a new batch. Delete Batch: Delete an existing batch. Edit Batch: Modify an existing batch. Read Batch: Read Only permission to view an existing batch. Set Active Batch: Allows shop floor operators to set the active batch for a workstation (inForce Line Attendant is required). More information: Log into Production and start work on a batch | |

Shop Floor | Change Notices | Create Change Notices: Create new change notices. Delete Change Notices: Delete existing change notices. Edit Change Notices: Modify existing change notices. Read Change Notices: Read Only permission to view existing change notices. More information: Access advanced Production features | |

Shop Floor | Change Product | Allow Change Product: Change a product. More information: Access advanced Production features | |

Shop Floor | Defect Management | Add Defect: Add a defect. Assign Defects by Operations: Defects are assigned at the operation level. Blocked Defect Override: Unblock a defect currently blocked from being closed. Close Defect: Close a defect. Delete Defect: Delete a defect. Edit Defect: Edit defect properties. False Defect: Flag a false defect. Open Defect: Flag an open defect. Repair Defect: Mark a defect for repair. Replace Part: Mark a defect for replacement. More information: Defect collection in the Hot Spot Viewer, Gadgets for Operator Interface templates | |

Shop Floor | FIFO WIP Control | Override FIFO WIP Control: Override FIFO WIP control validation errors, causing out-of-order units to be started successfully. | |

Shop Floor | Inventory Management | Allow New Inventory Bypassing Receiving Process: Add new inventory, bypassing the normal receiving process associated with the part/vendor. Create Inventory: Create new inventory. Delete Inventory: Delete existing inventory. Edit Inventory: Modify existing inventory. Read Inventory: Read existing inventory. | |

Shop Floor | Last Barcode Sequence Index | Reset Last Barcode Sequence Index: Reset the last index stored for generating sequential barcodes. The reset is performed at the Global, Part, Batch, or Revision level. | |

Shop Floor | Material Handling | Deliver Materials: Permission to deliver materials. This option is in the Advanced Features area of Production and is specific to Logistics and kitting materials to batches. Return Materials: Permission to return materials to stock. This option is in the Advanced Features area of Production and is specific to Logistics and kitting materials to batches. | |

Shop Floor | Material Setup | Override Depleted Materials: Allows a user to override depleted materials validation errors, causing consumption of depleted materials when units are finished. Override Exclusive Usage of Kitted Material: Allows a user to override restricted use of kitted material. | |

Shop Floor | Measurement Correction | Allow Measurement Correction: Allows a user to correct measurement units used in Production. More information: Access advanced Production features, View and manage measurements for parts and assemblies | |

Shop Floor | Operation | Allow Entry Conditions Supervisory Override: Allows the user supervisory confirmation to bypass all entry conditions. View without Certifications: Allows a user to view an operation without requiring any specific certifications, but not make changes. | |

Shop Floor | Operation Access | On Hold Override: Gives a user the right to override an operation that is on hold. | |

Shop Floor | Packout | Add To Box: Allows a packout user to pack items into a box. Clear All Items From Box: Allows a packout user to remove the content from a box. Complete Box: Allows a packout user to close a box. Complete Partially Packed Box: Allows a packout user to save a partially-filled box. Create New Box: Allows a packout user to register a new instance of a box. Reload Packing Items: Allows a packout user to reload the packing items. Remove From Box: Allows a packout user to remove an items from a box. | |

Shop Floor | Product Administration | Allow Reordering of Circuit Identifiers: Allows a user to reorder circuit IDs. Change Identifier: Allows a user to change circuit IDs. Delete Identifier: Allows a user to delete circuit IDs. | |

Shop Floor | Product Scrapping | Add new reason codes for product scrapping: Allows the user to add new reason codes to be used for product scrapping. Allow Product Scrapping: Permission to scrap products. More information: Add a new quality sampling plan | |

Shop Floor | Product Unscrapping | Allow Product Unscrapping: Permission to unscrap products. | |

Shop Floor | Quantity Adjustment | Add new reason code for quantity adjustment: Allows the user to add new reason codes to be used for quantity adjustments. | |

Shop Floor | Reason Code Management | Associate Reason Codes: Allows the user to associate reason codes to machine states. Edit Reason Codes: Edit reason codes. More information: Reorder parts | |

Shop Floor | Report Scheduling | Allow Report Scheduling: Allows the user to open the Report Scheduler environment. | |

Shop Floor | Shipping | Quantity Enforcement: Permission to enforce quantities (either with warnings or errors). | |

Shop Floor | Site Location Management | Edit Site Locations: The ability to edit the site location where a non-conformance occurred, for example the name of a factory or field location. | |

Shop Floor | Source Management | Edit Source: The ability to edit the source of a non-conformance, for example: Receiving, Engineering, Customer, Production. | |

Shop Floor | Sub-Assembly Removal | Allow Sub-Assembly Removal: Permits the removal of selected sub-assemblies. | |

Shop Floor | Sub-Assembly Replacement | Allow Sub-Assembly Replacement: Permits the replacement of selected sub-assemblies with different sub-assemblies. Replacement Override: Allows supervisory confirmation to replace sub-assemblies of unknown origin. | |

Shop Floor | Symptom Management | Add Symptom: Add a symptom. Close Symptom: Close an existing symptom. Delete Symptom: Delete an existing symptom. Edit Symptom: Modify an existing symptom. False Symptom: Flag a false symptom. Open Symptom: Flag an open symptom. Repair Symptom: Repair an existing symptom. | |

Shop Floor | Touch Time WIP Transaction Editing | Edit Touch Time: Modify WIP transaction touch time information. | |

xTend API | Connection | Use the xTend API: Connect to and use the xTend API. |